Digital Twin

It was 2 AM on a rainy Tuesday when Dr. Sara Miller’s phone buzzed. It was the Catastrophe Call. A -80°C ultra-low freezer had failed in her laboratory at a prestigious university in Boston. There were three years of stem cell research, irreplaceable samples that represented millions of dollars and thousands of hours of work inside the freezer. By the time Sarah ran across the city and arrived at the laboratory, the internal temperature had risen to critical levels. All the materials stored in the fridge got damaged. Sarah stood there, staring at the thawing vials, wishing she had a time machine. She did not need to go back so far. She thought it was just enough to know that the compressor was vibrating oddly two days ago. This heartbreak is a relatable reality for many researchers across the country. But what if she did not need a time machine? What if she had a virtual crystal ball instead? This is where the concept of Digital Twin Technology enters the room.

What is a Digital Twin?

A Digital Twin is a virtual replica of a physical object or a system. It is a computer program that takes real-world data of a physical object and creates a living, breathing digital mirror of it. But it is not just a 3D model or a static blueprint. It is dynamic. The temperature in the digital twin rises instantaneously if the temperature in the real laboratory rises. It is a bridge between the physical and the virtual world. This is a survival tool for US Research labs that often race against time and face funding cuts.

Digital Twin Technology

You might be wondering, “How can a computer model know the condition of the freezer?” This is the power of Digital Twin Technology. It relies on sensors and the Internet of Things (IoT).

Data such as temperature, vibration, humidity, energy usage, and airflow are collected continuously using sensors placed on the equipment. This data is fed into the digital model. The technology uses advanced analytics to learn what the physical equipment looks like when it is normal.

Digital twin technology can detect something that human ears and eyes cannot.

| Feature | Traditional Lab (The “Old Way”) | Digital Twin Lab (The “New Way”) |

| Equipment Repair | Fix it after it breaks and ruins samples. | Fix it before it breaks (Predictive Maintenance). |

| Lab Safety | React to alarms after smoke/gas is detected. | Simulate hazards digitally to prevent them from happening. |

| Energy Bills | Lights and AC run 24/7, wasting money. | Systems adjust automatically based on who is in the room. |

| New Experiments | “Trial and Error” (Hope it works). | “Simulate and Succeed” (Know it works). |

Why Research Laboratories are the Perfect Candidates?

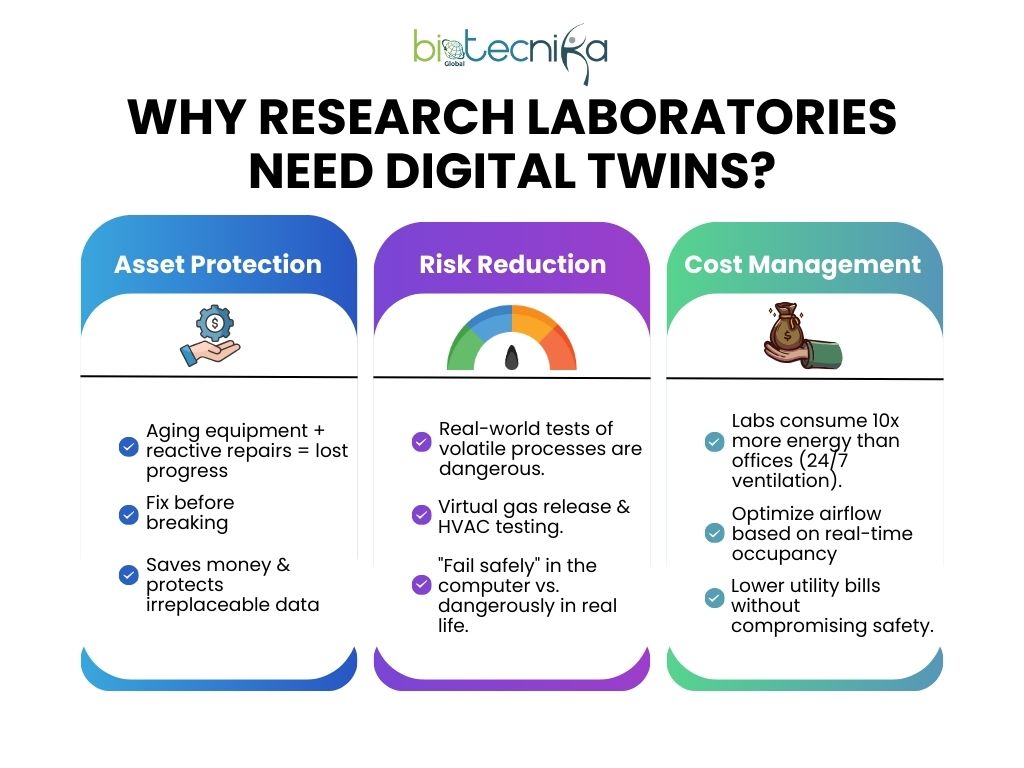

Laboratories are complex systems that deal with biological hazards, volatile chemicals, strict airflow requirements, and expensive machinery. Here is why every US lab needs to adopt this model immediately.

1. Predictive Maintenance

Equipment failure is the enemy of progress. In many US research laboratories, the equipment is getting older. A digital twin moves a lab from reactive maintenance to predictive maintenance. This means that fixing the equipment before it breaks and not when it breaks. This could save lots of money. But more importantly, it saves the data.

2. Safety Simulations

When a lab manager wants to introduce a new and volatile chemical process into the workflow, many factors must be considered. They have to conduct risk assessments and hope the ventilation calculations are correct.

With a Digital twin, they can run a simulation first. Then release virtual gas into the virtual lab and monitor how the HVAC system handles it. All the actions are monitored through the computer. The safety may fail in the computer; so we don’t fail dangerously in real life.

3. Energy Efficiency

The research labs in the US consume nearly 10 times as much energy as typical office workspaces. They are energy hogs. Ventilation systems run 24/7. Based on occupancy, the lab managers can optimize airflow using a digital twin. The digital twin saves thousands of dollars in electricity bills without compromising safety. If the digital twin detects that there are no researchers in Zone B, it can safely instruct the building management system to reduce the air-exchange rate.

The Competitive Edge for US Science

The global scientific community is becoming more competitive. Funding is becoming tight. The research labs in the US are under pressure to produce faster and at a lower cost. Optimizations of the layout can be done when a Digital Twin is adopted. They can digitally rearrange the benches and equipment to see what workflow provides the most efficiency for the scientists. Researchers can focus on what they do best in discovery, as the digital twin removes friction from the physical space.

We are no longer in an era where we have to wait for things to break. We don’t have to guess if a lab layout will work or hope that the ventilation is sufficient. Digital Twin is the ultimate partner for modern researchers. It creates a safety net that protects the science, the budget, and the people. It is time for the research laboratories to step into the future, one digital replica at a time.